Lasting Practices in Transformer Oil Recycling for a Greener Future

Lasting Practices in Transformer Oil Recycling for a Greener Future

Blog Article

Transform Waste Into Value With Advanced Transformer Oil Recycling

The makeover of waste right into value offers a critical possibility within the electrical sector, especially with the lens of innovative transformer oil recycling. By utilizing cutting edge modern technologies, such as vacuum cleaner distillation and purification systems, companies can recover vital sources from used transformer oil while minimizing environmental risks. This method not only enhances functional performance but likewise straightens with growing sustainability demands. As sectors increasingly prioritize eco-friendly efforts, the effects of these innovative recycling methods call for closer exam to understand their full capacity and influence on the marketplace.

Understanding Transformer Oil

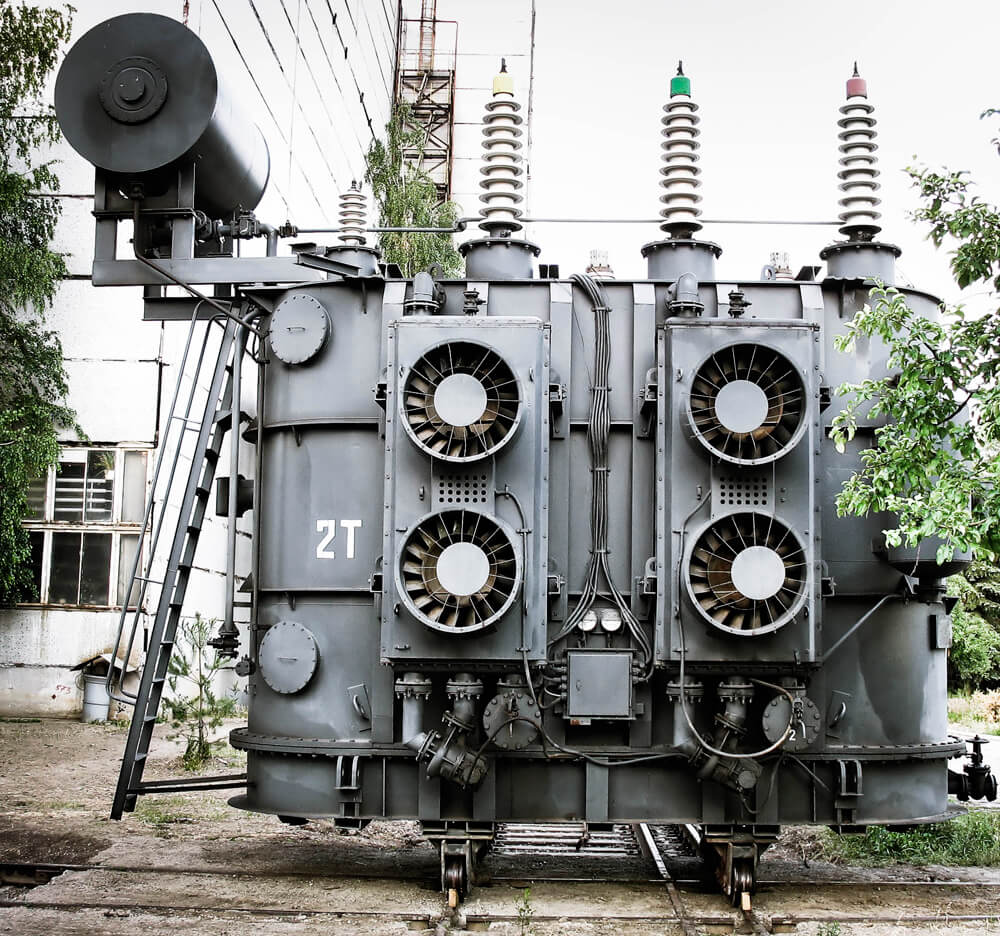

Transformer oil is a specialized cooling down and protecting fluid used in electric transformers to improve operational efficiency and integrity. This oil plays a crucial duty in protecting against electric discharges and preserving the required thermal balance within the transformer - Re-refining Transformer Oil. It serves to protect the conductive components, ensuring that power is properly moved while decreasing the risk of short circuits

Typically originated from improved petroleum, transformer oil is identified by its high dielectric toughness, low thickness, and a durable chemical stability that permits it to stand up to elevated temperature levels. The oil's capability to dissipate warmth created during procedure is critical; as transformers convert electrical power, they produce heat that should be effectively managed to avoid equipment failing.

Furthermore, transformer oil is formulated to withstand oxidation and destruction, which can cause the development of sludge and other unsafe byproducts. Routine surveillance of oil top quality is necessary, as contaminants can endanger its protecting residential properties and total efficiency. Recognizing the make-up and capability of transformer oil is vital for upkeep methods, making sure the long life and functional stability of transformers in different applications throughout the power industry.

Relevance of Recycling

Why is recycling transformer oil important for both environmental sustainability and economic efficiency? The incorrect disposal of transformer oil can bring about serious environmental threats, consisting of soil and water contamination. By recycling this beneficial resource, we not just mitigate these threats yet also add to a cleaner environment. Utilized transformer oil consists of hazardous materials that, if released into the setting, can harm wildlife and disrupt local ecosystems. Recycling assists to protect against these damaging impacts, reinforcing the commitment to ecological stewardship.

From an economic viewpoint, recycling transformer oil offers considerable expense savings for organizations. The procedure allows companies to reclaim a premium item that can be reused in different applications, lowering the requirement for purchasing new oil. This not only decreases functional costs yet likewise reduces garbage disposal expenditures linked with hazardous materials. Recycling supports the round economy by transforming waste right into beneficial sources, thus fostering sustainable practices within the sector (Re-refining Transformer Oil).

Advanced Recycling Technologies

As the need for sustainable techniques in the power sector expands, progressed recycling modern technologies have actually emerged as a crucial remedy for processing made use of transformer oil. These technologies include a variety of innovative techniques made to efficiently recover beneficial resources while reducing environmental influence.

One noticeable technique is vacuum purification, which divides oil parts at reduced temperatures, preserving the high quality of the base oil while eliminating impurities. This approach enhances the recuperation price and ensures that the recycled oil satisfies market requirements. An additional significant improvement is using adsorption and purification systems, which make use of specialized products to record pollutants and bring the original source back the oil's homes effectively.

Additionally, the integration of chemical therapies, such as neutralization and decolorization, plays a vital function in refining transformer oil. These processes get rid of acids, sludge, and discoloration, leading to high-grade recycled oil that can be recycled in numerous applications.

Economic and Environmental Conveniences

The financial and environmental advantages of transformer oil recycling are significant, providing a dual benefit for both sector stakeholders and environmental conservation. By reprocessing made use of transformer oil, companies can considerably decrease operational costs connected with buying new oil, hence enhancing their profits. This procedure not just reduces garbage disposal fees yet additionally enables for the recovery of beneficial materials, generating extra income streams.

From an ecological viewpoint, reusing transformer oil adds to a reduction in pollution and source depletion (Recycling Transformer Oil). Proper recycling procedures reduce the risk of unsafe spills and dirt contamination, promoting and safeguarding regional ecosystems biodiversity. Repurposing transformer oil decreases the need for virgin oil extraction, which frequently includes environmentally destructive methods such as drilling and refining.

In addition, taking on innovative recycling technologies boosts conformity with rigorous ecological laws, therefore shielding firms from possible liabilities and fines. The positive influence on corporate social obligation campaigns can improve a business's online reputation, promoting better depend on and commitment amongst stakeholders and customers. Fundamentally, the ecological and economic advantages of transformer oil recycling emphasize its significance as a lasting method in the energy sector.

Future of Transformer Oil Recycling

Building on the significant economic and ecological benefits highlighted, the future of transformer oil recycling appears promising, driven by technological improvements and increasing regulative stress. Developments in reusing innovations, such as enhanced filtration systems and chemical handling techniques, are anticipated to enhance the performance and effectiveness of oil recovery processes. These innovations not only reduce waste yet likewise maximize the high quality of recycled oil, making it better for reuse in numerous applications.

In addition, as federal governments and governing bodies globally implement more stringent ecological guidelines, the need for lasting practices will climb. This change will certainly oblige wikipedia reference sectors to take on transformer oil reusing as a vital element of their functional strategies. Companies that prioritize eco-friendly techniques are likely to get an one-upmanship, attracting environmentally aware customers and stakeholders.

Final Thought

The recycling of transformer oil with sophisticated technologies not only preserves beneficial sources however likewise substantially alleviates environmental threats linked with garbage disposal. By embracing innovative techniques such as vacuum distillation and filtration, the electrical market can improve sustainability while simultaneously minimizing functional expenses and producing revenue. As the emphasis on eco-friendly techniques increases, the future of transformer oil recycling appears encouraging, positioning firms to flourish in an increasingly open market that prioritizes sustainability and published here ecological responsibility.

Transformer oil is a specific insulating and cooling down fluid made use of in electrical transformers to enhance operational performance and dependability. Understanding the make-up and capability of transformer oil is crucial for upkeep techniques, making certain the long life and functional stability of transformers in various applications throughout the power market.

One famous strategy is vacuum distillation, which divides oil components at reduced temperatures, maintaining the quality of the base oil while getting rid of impurities. By reprocessing used transformer oil, firms can considerably lower functional costs connected with acquiring new oil, therefore enhancing their lower line. Repurposing transformer oil lowers the need for virgin oil extraction, which typically includes environmentally harmful methods such as exploration and refining.

Report this page